Smart safety control system

Engineered by Marble Control Systems

Engineered by Marble Control Systems

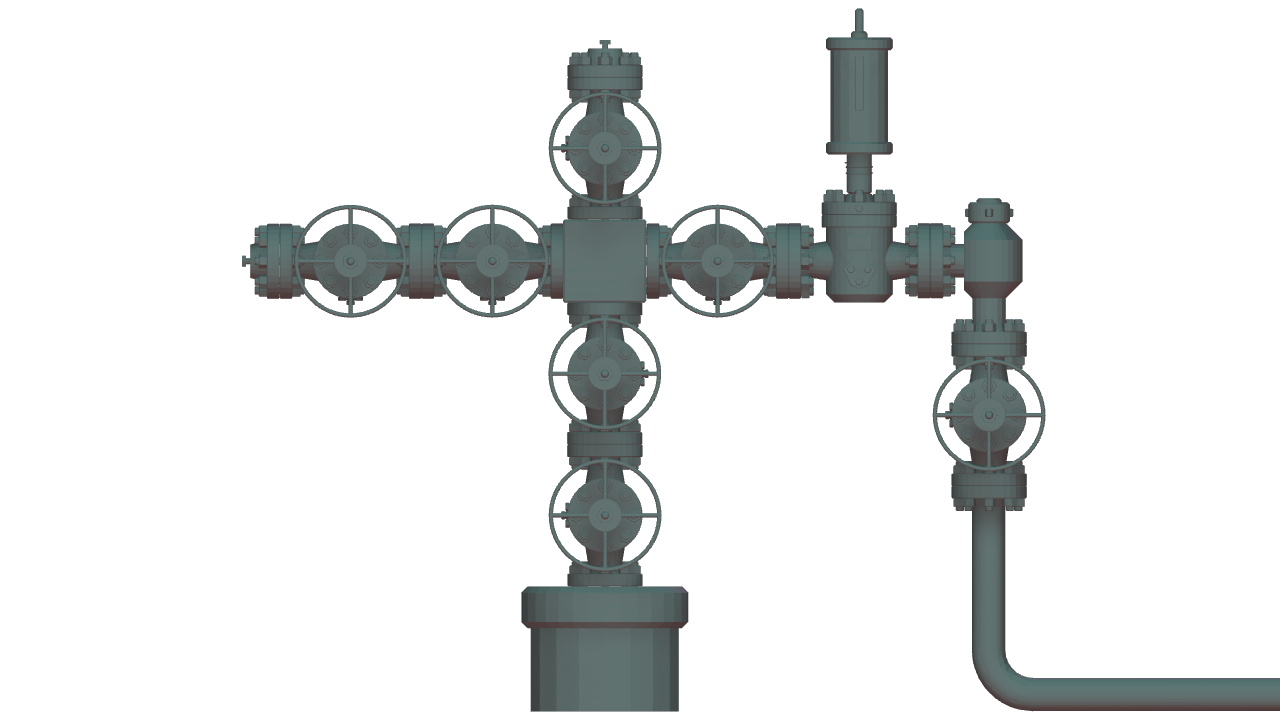

An independent safety control system developed to safeguard your production infrastructure by managing hydraulic operated valves. Onshore or offshore, on-site or remotely the CAMEL is designed to protect oil and gas production systems.

The CAMEL helps operators to detect anomalies while in service and prevent valve’s damage by performing automatic or manual Partial Stroke Tests.

Valve is currently open.

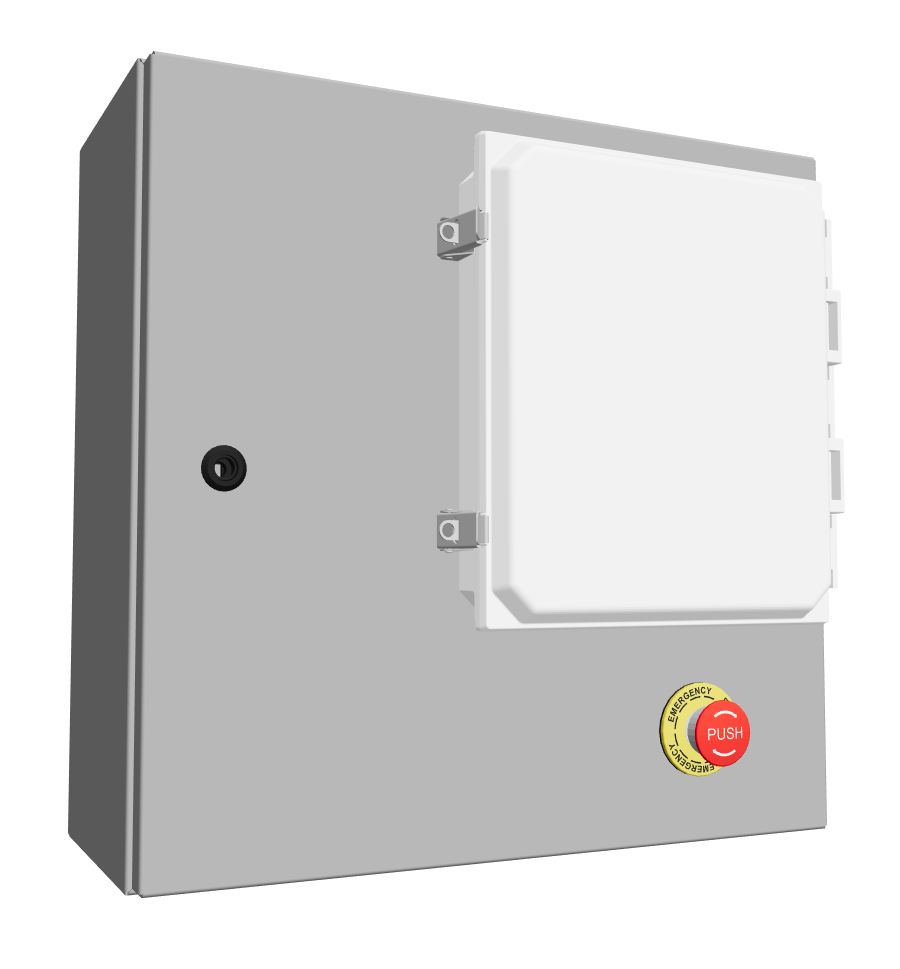

Simple installation and commissioning.

Probability of Failure on Demand (PFD) between 0.01 to 0.001.

Embedded in a 7” Touchscreen to setup and monitor the CAMEL.

Analyse the CAMEL’s log to detect anomalies and Schedule maintenances.

Modular design to simplify maintenance, reduce on-site interventions and improve production uptime.

Monitor CAMEL's activity log thru instant notifications directly to your smartphone, tablet or PC.

Stay informed about your CAMEL system's behaviour remotely. Our new WEB application allows you to get PUSH notifications directly to your smart device or computer every time an event activates.

CAMEL can be anchored to the ground* providing control over the valve regardless of the operator’s location.

*Skid required and sold separately upon client’s request.

The CAMEL automatically balances the hydraulic system in order to mantain a stable pressure inside the actuator’s chamber reducing the operator’s intervention and eliminating progressive closures frequently present in conventional mechanical-hydraulic control systems.

Using an electro-hydraulic pump the CAMEL ensures enough flow and pressure is available to the hydraulic actuator keeping the valve open.

If closing is required, a solenoid valve commands the electro-hydraulic pump causing the actuator’s pressure to fall.

The CAMEL is capable to operate in remote locations where external power sources are not available providing a reliable fail-safe shutdown system when pressure falls outside of the preset ranges.

After a fail-safe operation occurred the CAMEL keeps the shutdown valve closed until the operator reopens it manually.

Monitor, log and store events and alarms exactly when they happen.

SCADA Integration available.

Analyze stored data thru proprietary Software application.

Remote communication thru PUSH notifications to mobile device, tablet or computer.

Flexible and user-friendly system for 24/7 notifications.

Take decisions based on up-to-date information for every system connected.

CAMEL can be 100% autonomous thru solar panel installation.